D941X Electric Flange Butterfly Valve Series

manufacturer: Kaiweixi Valve Group Co., Ltd

Eml: Carrie@kaiweixi.com

Tel: +86 (577) 67038872

Mob: +86 189 6779 6392(WeChat Same Account)

product drawing

D941X Electric Flange Butterfly Valve Series

Overview

The D941X Flange Electric Butterfly Valve is a type of valve that uses an electric motor as the driving source to control the 90-degree rotational movement of the disc for opening, closing, or regulating the medium in a pipeline. This valve adopts a flange connection method, securely fastened to the pipeline flanges via bolts, ensuring stable and reliable installation. Upon receiving control signals, the electric actuator transmits the motor's rotational torque to the valve stem through an internal gear drive or worm gear mechanism, thereby driving the attached disc to rotate precisely within the valve body. The disc sealing surface is typically overlaid with elastic materials such as rubber, forming an interference fit with the valve seat on the inner wall of the valve body to achieve bidirectional soft sealing. The D941X Electric Butterfly Valve features simple operation, a high degree of automation, and the capability for remote and intelligent control. It is widely used in water supply and drainage, HVAC, fire protection, power systems, and industrial automation applications.

Features

1、Electric Intelligent Control: Equipped with an integrated or split-type electric actuator capable of receiving 4-20mA or on/off signals for precise control. Supports remote operation, automatic regulation, and centralized control, offering a high degree of intelligence.

2、Sturdy Flange Connection: The valve body features a standard flange end face design, ensuring high connection strength and excellent sealing performance. Installation is stable and secure, making it suitable for medium- and high-pressure pipeline systems.

3、High-Performance Soft Seal: The disc sealing ring is integrally overlaid with elastic materials such as EPDM, NBR, or FKM, providing superior sealing performance. Capable of achieving bidirectional zero leakage (sealing class up to Class VI).

4、Low Flow Resistance & Energy-Saving Design: When fully open, the disc thickness is the only obstruction in the flow path, resulting in an extremely low flow resistance coefficient. This effectively reduces pressure loss in the pipeline system and saves operational energy consumption.

5、Compact and Durable Structure: Compared to gate valves of the same diameter, it features a shorter face-to-face length and lighter overall weight, occupying minimal space. Key components are made of stainless steel or copper alloy, offering strong corrosion resistance and a long service life.

6、Versatile Control Modes: Offers multiple control modes including on/off and regulating types. Can be equipped with features such as limit switches, torque protection, and manual/automatic switching to adapt to various operational requirements.

7、Easy and Economical Maintenance: Modular design allows for convenient replacement of main sealing components. The electric actuator boasts a high protection rating (typically IP67), suitable for harsh environments like humidity and dust, resulting in low maintenance costs.

8、Safe and Reliable Operation: Includes functions such as overload protection and signal loss self-locking, ensuring safe and reliable valve performance under abnormal conditions and preventing system failures.

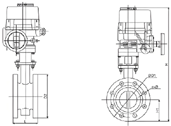

Dimensions & constructral diagram

D941X Electric Flange Butterfly Valve Series constructral diagram(pic1)

The main technical parameters

| Name | Material |

|---|---|

| Valve Body | Gray Cast Iron, Ductile Iron, Carbon Steel |

| Disc | Carbon Steel with Rubber Lining, Carbon Steel with Fluoroplastic Lining, Stainless Steel, Duplex Stainless Steel Plate 1.4529, C276 |

| Valve Seat | Natural Rubber, EPDM |

| Valve Stem | Stainless Steel, 2Cr13, 304 |

Standard

| Item | Specification | Unit |

|---|---|---|

| Nominal Pressure | 1.6 | PN |

| Strength Test Pressure | 2.4 | MPa |

| Seal Test Pressure | 1.76 | - |

| Operating Temperature Range | ≤80 | ℃ |

The main external and connection dimensions

| Specifications | Configuration | D1 | D2 | H | H1 | L | n-Φd | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | ||||

| 50 | 2' | LQ1-6 | 125 | 160 | 454 | 84 | 108 | 4-18 | |||

| 65 | 2.5' | 145 | 180 | 459 | 75 | 112 | 4-18 | ||||

| 80 | 3' | 160 | 195 | 499 | 102 | 114 | 4-18 | 8-18 | |||

| 100 | 4' | LQ1-10 | 180 | 215 | 521 | 113 | 127 | 8-18 | |||

| 125 | 5' | 210 | 245 | 553 | 129 | 140 | 8-18 | ||||

| 150 | 6' | LQ2-20 | 240 | 280 | 629 | 143 | 140 | 8-23 | 12-23 | ||

| 200 | 8' | LQ3-35 | 295 | 335 | 741 | 170 | 152 | 12-23 | 12-25 | ||

| 250 | 10' | LQ3-50 | 350 | 355 | 390 | 405 | 818 | 201 | 165 | 12-23 | 12-25 |

| 300 | 12' | LQ4-80 | 400 | 410 | 440 | 460 | 929.5 | 221 | 178 | 12-23 | 12-25 |

| 350 | 14' | LQ4-110 | 460 | 470 | 500 | 520 | 1002.5 | 253 | 190 | 16-23 | 16-25 |

| 400 | 16' | LQ4JS-200 | 515 | 525 | 565 | 580 | 1173.5 | 284 | 216 | 16-25 | 16-30 |

| 450 | 18' | 565 | 585 | 618 | 640 | 1248.5 | 319 | 222 | 20-25 | 20-30 | |

| 500 | 20' | 620 | 650 | 670 | 705 | 1331.5 | 359 | 229 | 20-25 | 20-30 | |